A Sanyo MDC-3300F radio/CD/MD which wasn’t playing any CDs. Put a CD in, and after a few seconds the display shows “CD NO DISK”

A Sanyo MDC-3300F radio/CD/MD which wasn’t playing any CDs. Put a CD in, and after a few seconds the display shows “CD NO DISK”

Usually it’s just the lens that needs cleaning, but I noticed that the CD wasn’t rotating at all, so something else is wrong.

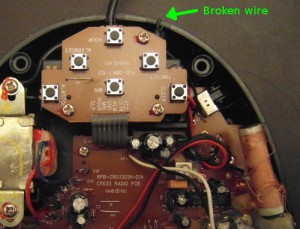

Having opened the case and removed the motor/sled module, I was able to test the motor and it was OK, so we delve further into the electronics. Wiring between the module and main PCB checks out OK but there’s no voltage on the first two pins. Time to unplug the power and dig further…

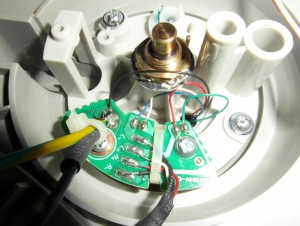

After much un-screwing of bits we reach the circuit board containing the LA6541 chip which drives the motor. (on the photo the PCB we’re looking for is underneath the vacuum fluorescent display, joined at right-angles to the main PCB. The minidisk module and display module need to be removed to get to it).

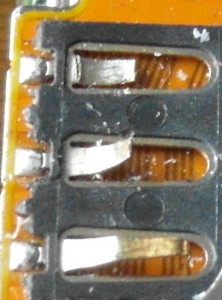

A few solder joints on the LA6541 chip look ‘dry’, so I carefully resolder them. It’s great that circuit diagrams are available for most electronic equipment these days. The chip shows no signs of having overheated, so confident that this was the problem I reassemble the unit.

Working again, I put the unit on soak test by playing a few CDs on it, start to finish. So far so good…

£10 charged as it was about an hours work, and the customer delivered and picked up the unit.

UPDATE 29/11/2015… After a few hours testing, it’s apparent that there is more wrong with this unit than I initially thought, as it ‘crashes’ and becomes completely unresponsive at random intervals. Suspect an intermittent problem with either the PSU or CPU/controller, so disassembled the unit for a second time for a visual inspection, re-seating the connectors, but without any improvement. I decide that it’s no longer spending more time/money on this, as intermittent faults like this can become very time-consuming; typically they will work perfectly when you’re trying to see why they are broken!

Handed back to the owner with no charge